Choke line friction (CLF) is the frictional pressure which is generated while circulating mud through choke or kill line. For surface stack, the choke line friction is negligible because the choke line is short therefore the friction pressure is so small. However, the choke line friction in deepwater operation has a big effect bottom hole pressure. Killing the well without considering the CLF will add excessive pressure and it increases the chance of fracturing formation at casing shoe or anywhere in the well.

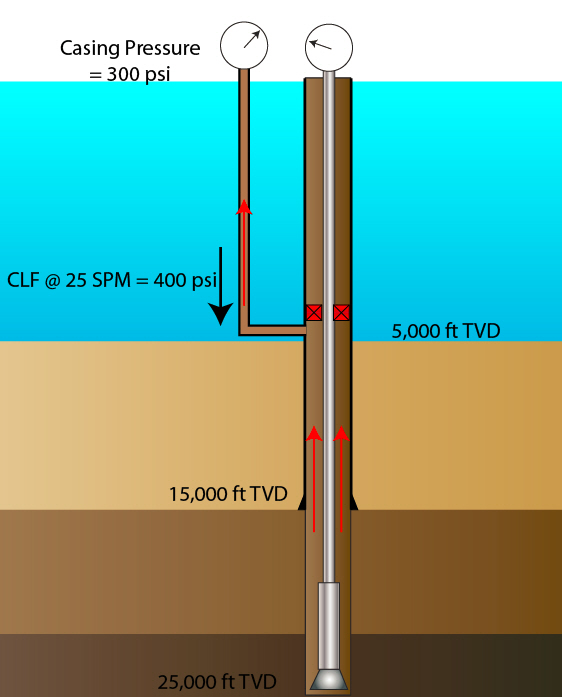

Figure 1 is a simple diagram showing the direction of CLF while a normal circulation is performed. The choke line friction will be in the opposite direction of flow which is downwards to the wellbore. This additional friction will increase the bottom hole pressure.

Figure 1 – Direction of Choke Line Friction Pressure

Example: Water depth = 5,000 ft

Shoe depth = 15,000 ft TVD

Hole depth = 25,000 ft TVD

Casing pressure = 300 psi

Current mud weight = 12.0 ppg

Choke line friction pressure @ 25 spm = 400 psi

Neglect annular pressure loss in the well due to low flow rate

Figure 2 - Example of CLF

What is the shoe pressure if we bring pump up to speed without considering CLF?

Figure 2 is the diagram based on the question and you need to add the CLF and casing pressure. Bottom hole pressure at the shoe is calculated by the following equation;

BHP @ shoe = MW + (Casing Pressure + Choke Line Friction) ÷ 0.052 ÷ Shoe TVD

BHP @ shoe = 12.0 + (300 + 400) ÷ 0.052 ÷ 15,000 = 12.9 ppg

Without compensating the CLF, the bottom hole pressure will increase by 0.9 pgg which can possibly break down the shoe.

In order to maintain constant bottom hole pressure, the casing pressure must be compensated by CLF. In the next topic, we will discuss how to measure CLF and maintain the bottom hole pressure while bring the pump up to speed.

Reference books:  Well Control Books

Well Control Books