Rotary drilling assemblies can typically control a directional of a well by having proper stabilizer placement. With this kind of drilling assembly, only inclination can be controlled and a well cannot be directionally oriented to required direction. In this article, it briefly describe how stabilizer placement can affect the well direction.

Rotary Build Assembly (Fulcrum Assembly)

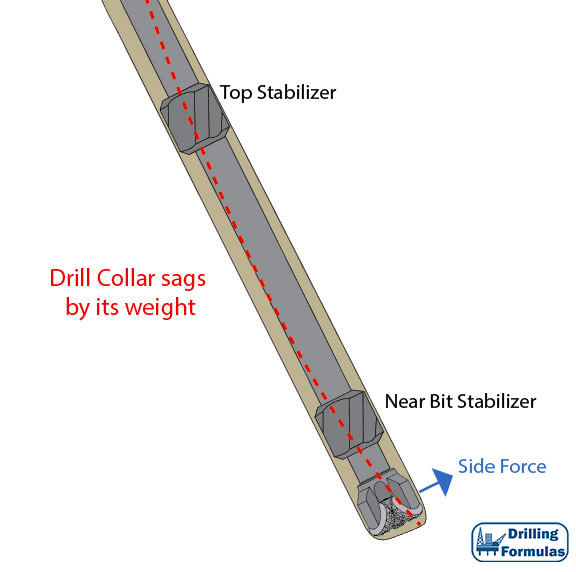

When a drill collar is supported at both ends but not held vertically, its own weight causes it to sag in the middle. This phenomenon is used in rotary drilling assemblies to create the necessary side force at the bit to alter the angle (Figure 1).

Figure 1 – A build rotary assembly

Stabilizers are used to force the drill collar sag to push the bit either to the low or high side of the hole, or alternatively to reduce side force. This is done by altering the position of the stabilizers, and having them either the same size as the drill bit (full gauge) or smaller (undergauge).

In order for a rotary build assembly to work, the hole needs to be somewhat inclined (over about 12°) to create the sag in the first place. A greater inclination means more side force is generated. The near bit stabilizer (NB stab) acts as a fulcrum, while the collars are like a lever, so that when one end is pushed down, the opposite end pushes up. When the NB stab is undergauge, it develops a smaller upwards side force, allowing the stabilizer gauge to have effect. Should the next stabilizer be undergauge, then the build effect increases as the ipper part of the lever moves downwards.

The bit is also greatly affected by the weight which is applied to it. If there is sag in the drill collars, then additional weight from above will increase the amount of sag, and the drill collar will begin to buckle. In practice, this means that when more weight is applied to a build assembly, it is able to build faster.

Rotary Drop Assembly (Pendulum Assembly)

In order to drop the angle, no near bit stabilizer (NB stab) will be run. In between the bit and the first stabilizer, there will be either 60 or 90 feet of drill collars. The force of the sag (subtracting the NB stab fulcrum) gradually forces the bit to the lower side, thereby decreasing the angle.

In order to begin the drop, a light weight is run on the bit. When the trend has been established, it may be increased by the addition of extra weight to the bit. This approach has its downsides, though- one of which being low stability. It will easily get knocked off course by natural formation trends, as well as dropping or running sideways. It is difficult to maintain azimuth, and it might therefore be necessary to trip the bit out of the hole entirely to alter the BHA configuration, s that it will follow the intended well path. Drop assemblies are also sometimes called “pendulum assemblies”, and an example of one is illustrated in Figure 2.

The drill bit itself also needs to be taken into consideration. Drill bits may be designed to provide some amount of side cutting action. This helps to increase the effectiveness of a build or drop assembly. In cases where the well must deviate by next to nothing at all, bits are also available which do not have this side cutting action. In the absence of this feature, the bit will attempt to drill in a straight line wherever possible.

Figure 2 – A rotary drop assembly

Rotary Holding Assembly (Packed Hole Assembly)

When the well is now pointed in the necessary direction, and at the proper angle, it can then be locked so that it drills in a straight line. This configuration is known as a packed hole assembly (since it is packed with stabilizers), or alternatively a still assembly because it is resistant to bending forces. An example of this assembly is shown in Figure 2 which shows that the drilling assembly consists of 3 stabilizers placed not far away from each other. With this type of assembly, the directional performance will not be as drastically affected by factors like natural formation trends, or the amount of weight on the drilling bit.

To achieve optimum drilling performance, it is frequently required that there is a high weight on the bit. A tangent assembly excels because it allows for this high weight, and subsequent fast drilling, without risking the hole getting knocked off course. Even packed assemblies are only able to build their speed slowly when high weights are used on it.

Rotary assemblies will tend to turn to the right as they drill. To offset this, the well may be kicked off and positioned to point ever so slightly to the left of the intended direct track, and also somewhat low. This means that the well will turn to the right and slowly build while still using the ideal parameters for fast drilling.

Figure 3 – A rotary holding assembly

It is also possible to run a locked assembly using a second stabilizer which is somewhat under gauge (Figure 4). Therefore, this leads to an additional build tendency because the under gauge stabilizer sag down and make the BHA acts like a building BHA (a fulcrum BHA).

References

Inglis, T.A. (2010) Directional drilling. Dordrecht: Springer-Verlag New York.

Mitchell, R.F., Miska, S.Z. and Aadnoy, B.S. (2012) Fundamentals of drilling engineering. Richardson, TX: Society of Petroleum Engineers.

National Oilwell Varco (2017) National Oilwell Varco. Available at: https://www.nov.com/Segments/Wellbore_Technologies/Dynamic_Drilling_Solutions/InTerra_Sensors_and_Systems/Directional_Systems.aspx (Accessed: 26 February 2017).

Schlumberger Limited (2017) Schlumberger Drilling Services. Available at: http://www.slb.com/services/drilling.aspx (Accessed: 25 February 2017).

Short, J.J.A. (1993) Introduction to directional and horizontal drilling. Tulsa, OK: PennWell Books.

Technical, T., Astier, B., Baron, G., Boe, J.-C., Peuvedic, J.L.P. and French Oil & Gas Industry Association (1990) Directional drilling and deviation control technology. Paris: Editions