We’ve learnt several topics in regard to casing design and this article will demonstrate you how to determine casing size in the well.

Casing size selection is determined from the inside outward and it starts from the bottom hole.

The sequence of design is based on the following steps;

1. Proper sizing of tubing is determined by inflow performance analysis.

2. Completion equipment is planned to install with tubing string. Determine which part has the biggest OD. This will directly impact of production casing.

3. Bit size for drilling the production section.

4. Casing size must be smaller than bit size and its ID must be bigger than the biggest component in completion string.

5. Once you get the last casing string, the upper string is selected by repeating bit selection and casing selection similar to step #3 and #4.

You may need to use the following table (Table 1) to determine bit size and casing size. This is based on API casing therefore if you use special casing, you may need to check with the casing company to give you exact casing ID.

Table 1 - Commonly Used Bit Sizes That Will Pass Through API Casing

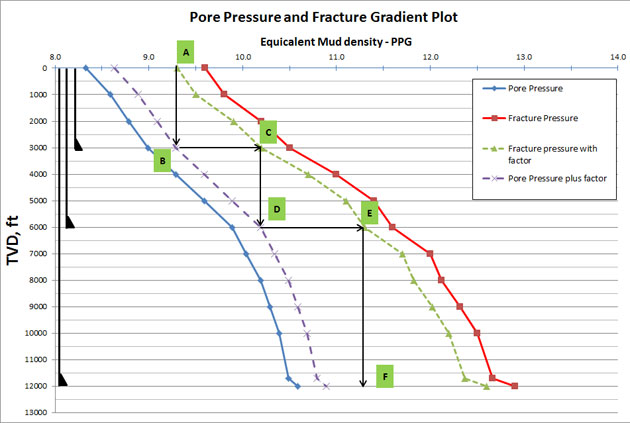

Example: According to the previous example, this is the casing design based on pore pressure and fracture gradient (Figure 1).

Figure 1- Casing Design Based On Pore Pressure and Fracture Gradient

The casing string should be set at 3000’ TVD, 6,000’ TVD and 12,000’ TVD.

The Rig needs to drill and set the conductor casing to 500’ TVD in order to rig up the well control equipment.

Completion information

• Tubing string – 3-1/2” tubing

• Completion equipment – TRSV, Side Pocket Mandrel, Packer, etc.

• The biggest size of completion equipment is 5 inch.

According to the Table 1, the bit and casing plan for this well is described below.

Note: this plan is based on size selection only. The load cases are not accounted for in this example.

Production Section

Bit size = 8-1/2”

Casing = 7”, 26 ppf, ID 6.276”

Intermediate Section

Bit size = 12-1/4”

Casing = 9-5/8”, 40 ppf, ID 8.835”

Surface Section

Bit size = 14-3/4”

Casing = 13-3/8”, 48 ppf, ID 12.715”

Conductor Casing

Bit size = 17-1/2”

Casing = 16”, 55 ppf, ID 15.375”

Figure 2 – Casing Details

In order to determine what casing grades to be used in the well, you need do the detailed calculations based on several load cases as burst, collapse, tensile, etc. We will cover the details later on.

Ref Book -> Applied Drilling Engineering Book special offer